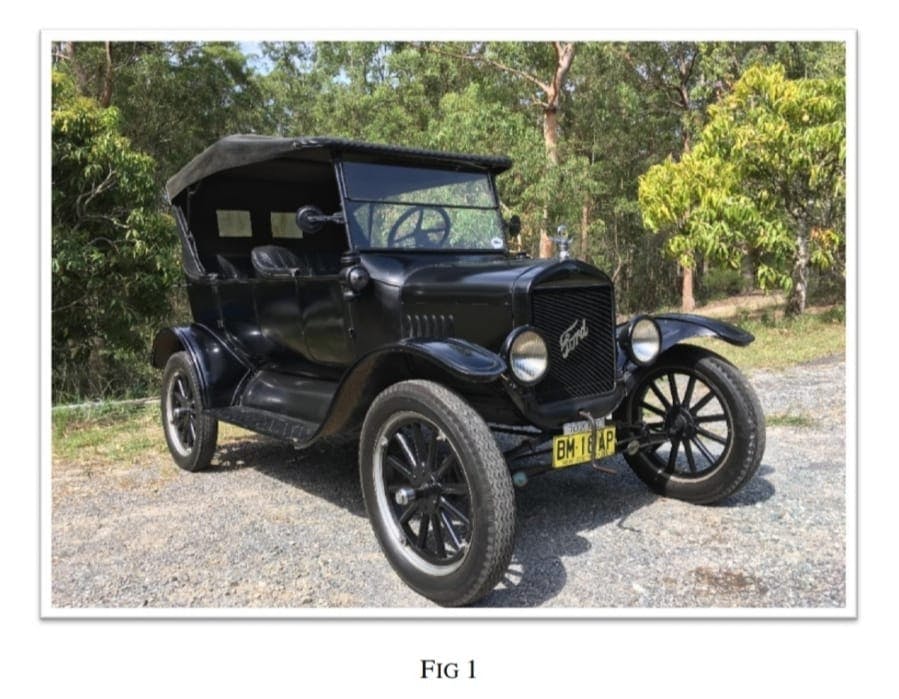

Mankind has been at the art of mastering transportation for over half a millennium now. The problem with all was that the machines necessary to provide the mechanical energy to move them were massive and required high maintenance. Since transportation was a necessity, mankind needed to further simplify it and the solution was found in the internal combustion engines that were commercially viable developed by Nikolaus Otto and Étienne Lenoir. They proved to be cheaper and required less maintenance and running costs. So in 1885 Karl Benz designed his own engine and launched it in his Motorwagen in Germany, it is regarded as the first practical automobile powered by an IC engine. But still, the cost of his vehicle units was very high and this challenge was taken up by Henry Ford, who in 1908 created the Ford Model T and mass-manufactured it and this was all that was needed to make the automobile industry seem viable and sustainable.

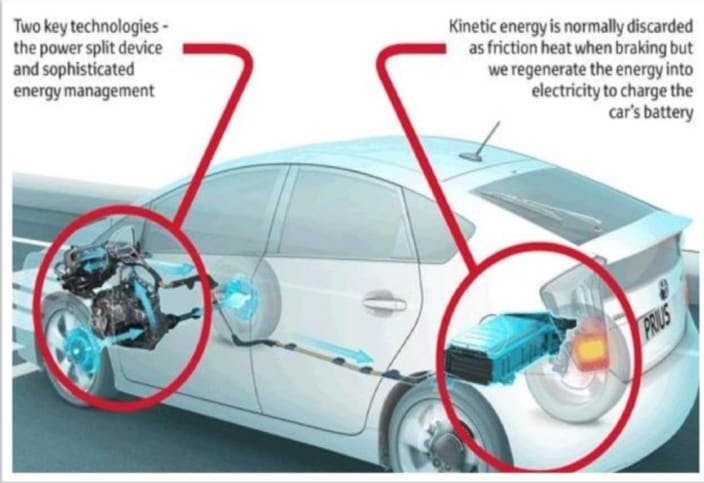

In the 20th century the primary concern for automobile manufacturers was to make the vehicle publicly viable and to create a sustainable market but entering into the 21st the primary concern for mankind was to create an eco-friendlier Environment. This couldn’t have been done by all the waste that IC engines produce, ideally the energy created by the combustion reaction in the engine should be fully converted to mechanical energy but to enable this conversion some amount of losses need to occur according to thermodynamics. Over the years these losses have been reduced and the engines have started becoming quieter and more efficient but nevertheless these losses still occur and regenerative braking provides the answer to ‘What can be the best out of this waste?’

There are basically two types of losses that can be recovered via regenerative braking, one is during braking and the other during the removal of the exhaust gases.

Regenerative braking gives us the means to harvest energy that is lost in a vehicle. To understand how this works we shall look into how the pioneers of vehicle technology do it Formula 1. But first let us briefly examine the goals that regenerative braking hopes to achieve.

To improve efficiency, we always have to look into ideal scenarios and in it once energy has been put in a system, it needs to be sufficient enough to make the system run, that is once the pedal is pressed the expended energy should be recovered and this energy should be fed back to run the vehicle rather than providing energy repeatedly. Regenerative braking provides us a means of using energy in a better way by repeatedly recovering and recycling energy.

Let’s understand why energy recovery is necessary in Formula 1

It can be clearly inferred from the below displayed figure that the number of turns in the above track is 19, including the hairpin. Wherever these turns are, the need for braking arises and here braking refers to reducing the vehicle speed from 313 kmph to 60 kmph within a matter of seconds. This means massive amount of kinetic energy of the vehicle is getting dissipated as heat during the braking of the vehicle and heat once dissipated cannot be recovered and here’s where the energy regeneration tech of the hybrid Power unit starts doing its magic. Modern Formula 1 cars aim to be as light as possible and having that extra fuel in your vehicle just adds onto the weight and this is contradictory to the design philosophy and refuelling vehicles during the pit stop is highly dangerous so these vehicles tend to run with as less fuel as possible and hence efficiency is the essential during power unit design.

Energy recovery in Formula 1 is done by the means of two MGUs (Motor Generator Unit) namely the MGU-H and the MGU-K. One recovers energy from the kinetic energy of the exhaust gases and the later during braking.

The ‘H’ in the MGU-H stands for heat and refers to the energy recovered from the turbocharger. A turbocharger is a mechanical component in high performance engines which helps in the extraction of performance and efficiency. When the exhaust gases are ejected from the exhaust pipe of the engine it is directed to the turbine of the turbocharger which has a fan like design, this starts rotating the shaft that it sits on and the other end of this shaft has a compressor which takes the incoming air which is required for combustion and compression. This compressed air gives more oxygen in a lesser volume and thus improves combustion. But, this compressed air starts heating up due to its now reduced volume and this reduces performance, so it is passed through a heat exchanger and then supplied to the piston chamber. The shaft of MGU-H is connected to the same shaft as the compressor and the turbine. When the turbine rotates, the shaft of the MGU-H also rotates and in such a case it acts as a generator and starts storing up energy in the battery of the vehicle. During engine start up and in cases when insufficient amount of exhaust gases is released the MGU-H acts as a motor and rotates the turbine shaft, thus making the turbine much more efficient.

The MGU-K on the other hand acts as a means to recover the waste kinetic energy during braking. The MGU-K is directly coupled to the drive shaft of the vehicle. During braking, Formula 1 cars have massive amounts of energy thus all the kinetic energy of the vehicle isn’t recovered to electrical energy as there isn’t much time, so a major chunk of the kinetic energy is dissipated as heat and some of it is recovered via the MGU-K. During the race there are certain engine modes and then there is the SOC mode. The SOC mode decides the proportion of braking and recovery of energy and also the consumption of recovered energy. If the driver is in qualifying or in scenarios where he needs to achieve the fastest lap, then the drivers turns the MGU-K completely off but in scenarios where a rival is expected to attack the driver, he starts building up energy. When the driver releases the accelerator pedal, the MGU-K engages itself and starts recovering energy and later during the race when the driver needs an extra surge of energy it acts as a motor and supplies near about 80HP of energy. During the entire race the driver dances between higher recovery and having higher braking.

Energy recovery done right can make future automobiles highly efficient and can help eliminate one major source of pollution in our planet. Regenerative Braking is truly the art of making the best out of waste.